Is solar cable different to normal cable?

In the ever - expanding realm of renewable energy, solar power has emerged as a frontrunner. As solar installations become more widespread, the question of whether solar cables are different from normal cables becomes increasingly relevant. The answer is a resounding yes, and this article will explore the key distinctions.

Application Scenarios

Solar Cables

Solar cables are specifically designed for use in photovoltaic (PV) systems. These systems are exposed to various environmental conditions, such as sunlight, temperature fluctuations, humidity, and mechanical stress. Solar cables are installed in outdoor environments, running from solar panels to inverters, charge controllers, and batteries. They need to be able to withstand long - term exposure to ultraviolet (UV) rays from the sun, which can degrade the insulation of ordinary cables over time.

Normal Cables

Normal cables, on the other hand, have a wide range of applications. They are used in indoor electrical wiring, for example, to power household appliances, lighting fixtures, and industrial machinery. In these indoor settings, the cables are generally protected from direct sunlight and extreme weather conditions. They are also used in some outdoor applications where the environmental stressors are not as severe as those in solar installations, such as low - voltage outdoor lighting in gardens.

Construction

Insulation Material

Solar cables typically use specialized insulation materials. Ethylene - propylene - diene - monomer (EPDM) or cross - linked polyethylene (XLPE) are common choices. EPDM has excellent resistance to UV rays, ozone, and weathering, making it ideal for solar applications. XLPE, when cross - linked, offers enhanced thermal stability and mechanical strength, which are crucial for withstanding the temperature variations in solar panel arrays.

Normal cables may use a variety of insulation materials depending on their application. For indoor wiring, polyvinyl chloride (PVC) is a popular choice due to its low cost and good electrical insulating properties. However, PVC is not as resistant to UV rays as EPDM or XLPE, so it is not suitable for solar cable applications.

Conductors

In solar cables, the conductors are often made of high - purity copper. High - purity copper has low electrical resistance, which is essential for minimizing power losses in the PV system. Since solar power generation is all about maximizing efficiency, even a small reduction in resistance can lead to significant savings in the long run.

Normal cables also commonly use copper conductors, but the purity requirements may not be as stringent in some applications. For example, in some low - voltage, short - distance wiring scenarios, the cost - effectiveness of using a slightly lower - purity copper may be prioritized over absolute minimum resistance.

Performance Requirements

Voltage and Current Ratings

Solar cables need to handle the DC voltages and currents generated by solar panels. PV systems can operate at a wide range of voltages, typically from 12 volts in small off - grid systems to over 1000 volts in large utility - scale solar farms. The cables must be able to safely carry these high - voltage DC currents without overheating or suffering from electrical breakdown.

Normal cables are designed to handle either AC or DC voltages, depending on their application. In household electrical systems, they are mainly designed for AC voltages of 110 - 240 volts. The current - carrying capacity of normal cables is determined by factors such as the size of the conductor and the intended use, but the voltage and current requirements are generally different from those of solar cables.

Durability and Longevity

Given the harsh outdoor environment of solar installations, solar cables are engineered for long - term durability. They are expected to have a lifespan of at least 25 years, which is in line with the typical lifespan of solar panels. This requires the cables to resist environmental degradation, including UV damage, temperature cycling, and moisture ingress.

Normal cables, while also designed to be durable, may not need to meet the same high - level durability requirements. In indoor applications, the lifespan of a cable may be more related to technological obsolescence or changes in building electrical requirements rather than environmental wear and tear.

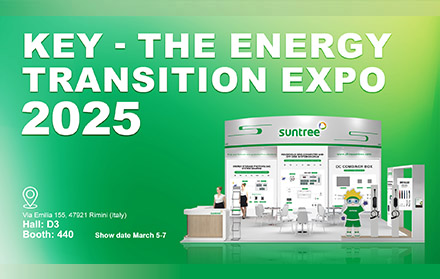

In conclusion, solar cables are indeed different from ordinary cables. Their unique design, structure and performance requirements are tailored to the specific needs of solar power generation systems. If you are involved in solar projects and seek high-quality photovoltaic products, then Suntree is your best choice. We are one of the top ten electrical export brands in China, with a wide range of AC DC products, exported in large quantities to more than 100 countries. Our in-house R&D team consists of more than 50 professionals and has obtained more than 100 PV patents. This expertise ensures that our products are not only of the highest quality, but also highly competitive in the global market. Explore our extensive product range and solutions at and let us help you build a more efficient and reliable solar system.